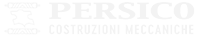

CONTINUOUS FLESHING MACHINE “SP” MOD FOR PELT AND HAIR HIDES

A new hydraulic power pack, and an electronic control of the conveying speeds.

Continuous fleshing allows to reach a very high productivity. With the fleshing technology developed by CM Persico during its 50 years of experience in the tanning sector, the quality of fleshing is at the highest achievable levels.

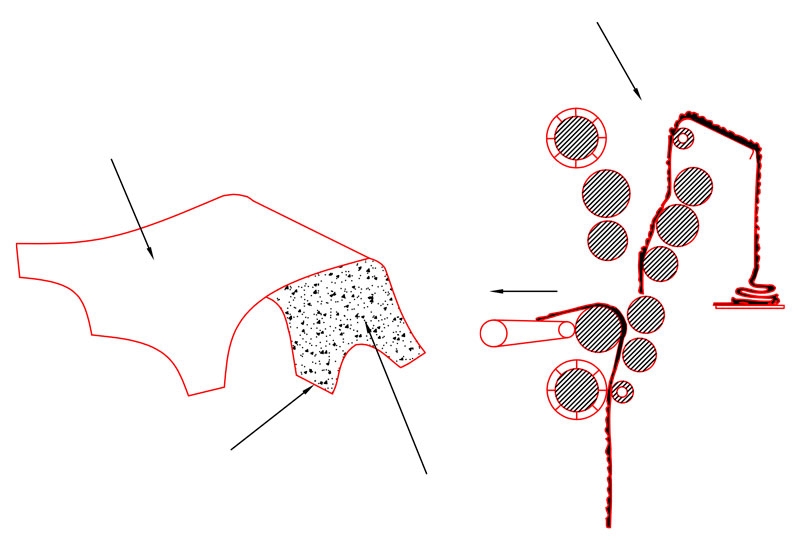

The leather is introduced from the part of the head into the upper part of the machine, with the operator’s command the fleshing bench is closed and the leather enters the machine; in this phase the tail is stripped. The operator monitors the progress of the operation and, at the right moment, the fleshing of the second half of the skin, the part of the neck starts with a control. At this point as fleshing continues, the leather is released from the exit belt at the front of the fleshing machine with the grain facing upwards and the tail in front.

Electrowelded and painted steel frame with the best technologies available on the market to avoid any type of corrosion over time.

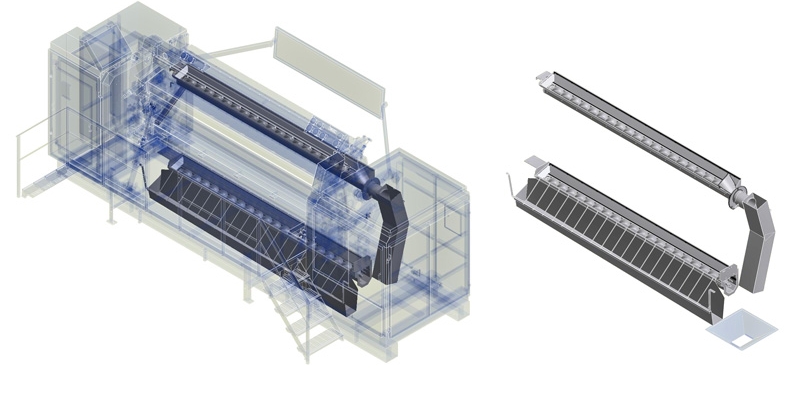

Group of augers for the transposed flesh

Installed in front of the fleshing rollers and is composed of two stainless steel hoppers containing two augers that rotate conveying the flesh into the hopper of the flesh pump.

A very reliable technology that, unlike traditional systems, does not use water to transport flesh.

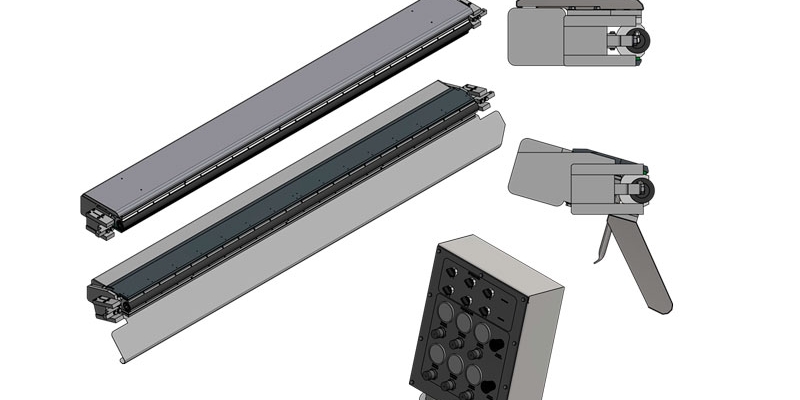

How does it work

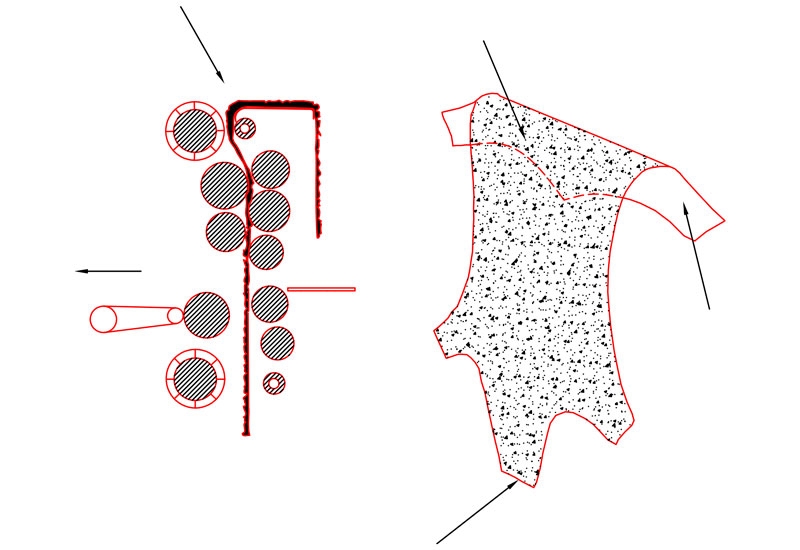

Phase 1

Insert the hide from the head. The hide is transported inside the machine and the rear part, the tail side, is fleshed.

Phase 2

The leather descends into the lower transport rollers until the operator sees the beginning of the fleshy part go by through the mirror.

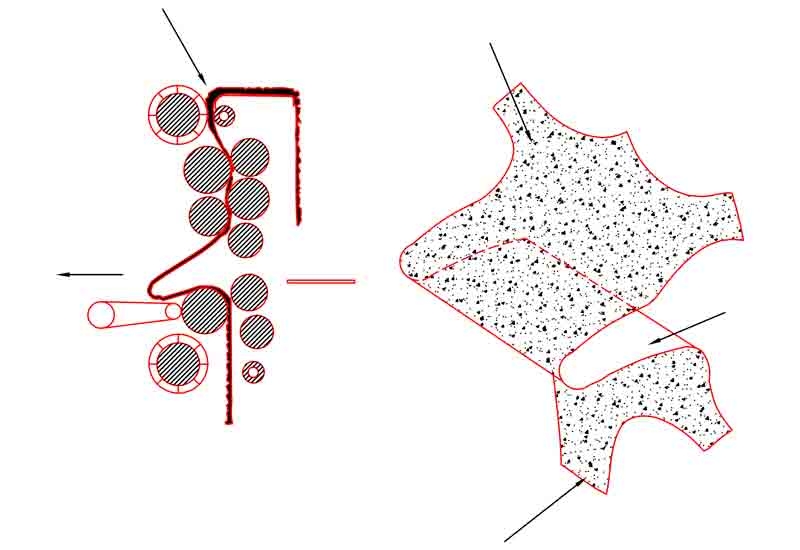

Phase 4

Opening of the swinging bench in the upper part and closing in the lower part.

Starting the fleshing in the lower part of the machine to flesh the second half of the hide, the part of the head.

With this, the fully processed hide comes out of the front of the machine on the exit belt with the tail in front and the grain side facing upwards.

Optional

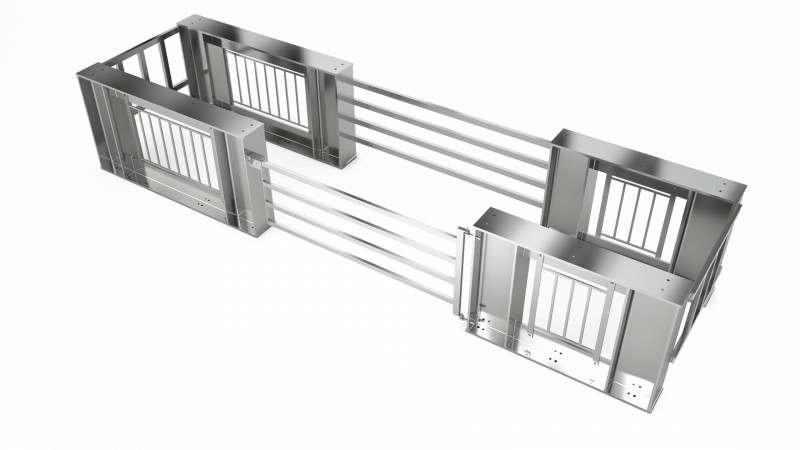

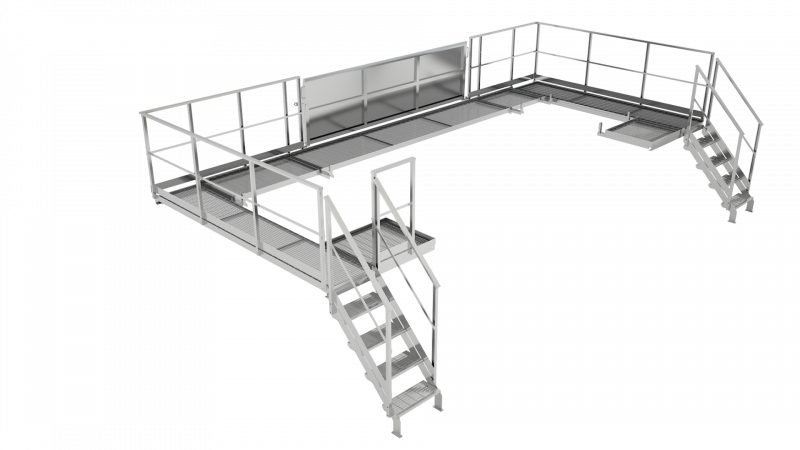

Raises for base

Hot galvanised steel risers are supplied on request for the installation of the fleshing machine at a height of 1.2m.

The risers include protections and gate with safety microswitch for maintenance.